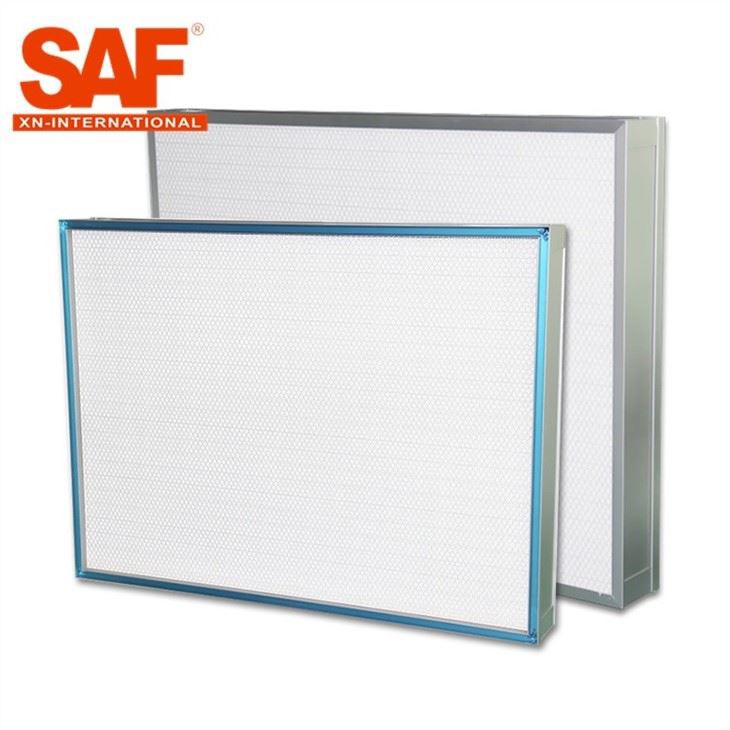

I. Product Introduction

High-efficiency particulate air (HEPA) filter with silicone gel sealing technology, achieving **>99.97% efficiency at 0.3μm** (EN 1822 H13-H14).

II. Product Advantages

Technical Benefit User Benefit Leak-proof Design ≤0.01% bypass (vs. 0.05% in traditional HEPA) Guaranteed ISO Class 5+ cleanroom compliance Low ΔP 30% reduced airflow resistance (vs. foam seals) Energy savings up to 15% Chemical Resistance Withstands VOCs, sterilants (H₂O₂, EtO) Longer life in harsh environments Easy Installation Snap-in gasket channel (no tools required) 50% faster replacement

III. Product Parameters

| Parameter | Value | Standard |

|---|---|---|

| Filter Class | H13 / H14 / U15 | EN 1822 |

| Efficiency | 99.97% @ 0.3μm (H13) | IEST-RP-CC001.6 |

| Initial Pressure Drop | ≤220 Pa (@ 0.45m/s) | ISO 14644-3 |

| Temperature Range | -30°C to +150°C | MIL-STD-282 |

| Frame Material | Anodized aluminum (1.5mm厚) | DIN 1886 |

IV. Product Applications

1. Semiconductor Fabs

- Use: Photolithography bay ULPA filtration (U15)

- Result: ≤1 particle/ft³ @ 0.1μm

2. Biopharma

- Use: Sterile filling line isolators

- Result: Meets EU GMP Annex 1 Class A

3. Hospitals

- Use: OR ventilation with H₂O₂ decontamination

- Result: 6-log spore reduction (per USP <797>)

4. Data Centers

- Use: Hyperscale server cooling air

- Result: ASHRAE 52.11 MERV16 compliance

V. FAQ

Q1: How does gel sealing outperform traditional methods?

A: Silicone gel maintains elasticity at -30°C~150°C, preventing brittle cracks (unlike PU foam). Passes ASTM D412 elongation tests.

Q2: Can filters be retrofitted into existing housings?

A: Yes, compatible with Camfil, Flanders, and AAF terminal housings (provide gasket profile CAD for verification).

Q3: What's the recommended replacement cycle?

A: 2-5 years under normal use; monitor ΔP with Magnehelic gauges(replace at 2x initial ΔP).

Hot Tags: Gel Sealing HEPA Filter, manufacturers, suppliers, factory, wholesale