The structural resistance of high-efficiency air filters (HEPA/ULPA) is a key indicator of their design quality, energy efficiency, and operating costs. Here is a concise interpretation of its core aspects:

I. Definition of Structural Resistance

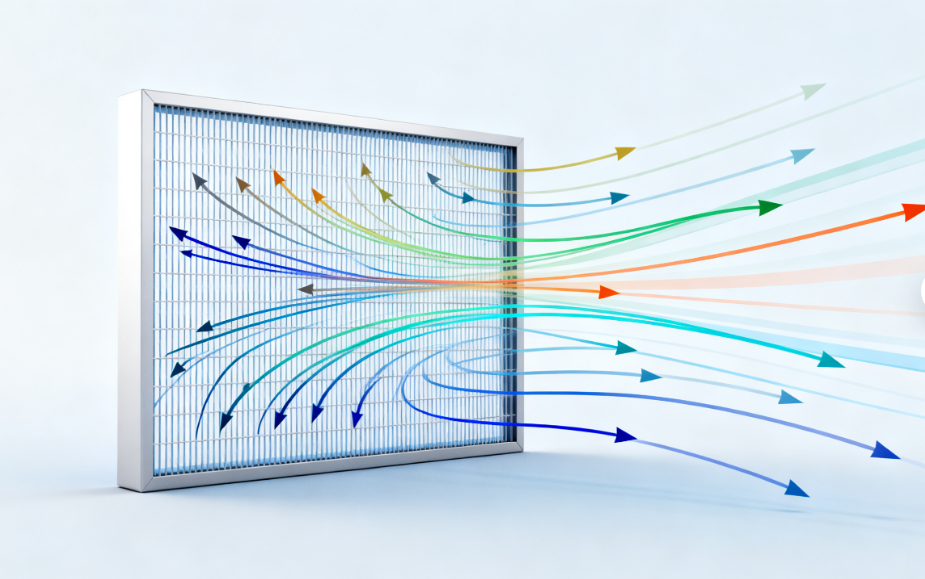

- Definition: Structural resistance, also known as the "initial resistance," refers to the pressure drop across a brand-new, dust-free filter at its rated airflow, measured in Pascals (Pa). It can be likened to the frictional force that air must overcome when passing through a clean, new filter mesh.

II. Importance of Structural Resistance

1. Energy Consumption: Higher resistance means more energy consumption by the fan. Lower initial resistance typically translates to greater energy savings.

2. Service Life: As dust accumulates, resistance increases until it reaches the "terminal resistance," at which point the filter needs replacement. A lower initial resistance means the filter has more "room to grow" before reaching this point, resulting in a longer service life.

3. Design and Manufacturing Quality: Low initial resistance indicates advanced filter media technology and skillful structural design.

III. Comprehensive Analysis of Structural Resistance

1. In Relation to Filtration Efficiency: The goal is to achieve the lowest possible resistance while maintaining the same level of filtration efficiency. High efficiency with low resistance is the hallmark of an excellent filter, whereas high efficiency with high resistance may suggest traditional or lower-quality filter materials.

2. In Relation to Filter Media: The filter media is crucial. PP/PET electret meltblown materials are the modern mainstream choice, easily achieving high efficiency with low resistance. In contrast, glass fiber, a traditional material, offers stable efficiency but typically has higher resistance.

3. In Relation to Structural Design: The larger the filter area, the lower the wind speed per unit area, and thus the lower the resistance. Pleat spacing must be precisely calculated; too small increases resistance, while too large wastes space. Aluminum foil separators are superior to adhesive line separators, ensuring smooth airflow.

4. In Relation to Rated Airflow: Resistance values must be compared at the rated airflow. Resistance values measured at different airflow rates are not directly comparable.

IV. Practical Interpretation

Consider two H13 high-efficiency filters:

- Filter A: Efficiency 99.97% (@0.3μm MPPS), initial resistance 120 Pa (@rated airflow)

- Filter B: Efficiency 99.99% (@0.3μm MPPS), initial resistance 150 Pa (@rated airflow)

Interpretation:

- Filter B has slightly higher efficiency but 25% higher resistance, suggesting Filter A may have a better "energy efficiency ratio."

- Ensure the test standards are consistent, especially the particle size basis for efficiency testing.

- Filter A likely uses more advanced filter materials and design, with a larger filter area.

- Filter A probably has a longer service life, lower long-term replacement costs, and lower disposal costs, even if its initial purchase price is higher.

Conclusion: Choose products that offer the lowest initial resistance while ensuring the required efficiency level to achieve lower energy consumption, longer service life, and lower total cost of ownership.